|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HANNOVER FAIR 1995 - 2019

HANNOVER FAIR 2019 HANNOVER FAIR 2019

HANNOVER FAIR 2018 HANNOVER FAIR 2018

HANNOVER FAIR 2017 HANNOVER FAIR 2017

Arno's Forum Interview 2017 Arno's Forum Interview 2017

HANNOVER FAIR 2016 HANNOVER FAIR 2016

HANNOVER FAIR 2015 HANNOVER FAIR 2015

HANNOVER FAIR 2014 HANNOVER FAIR 2014

HANNOVER FAIR 2013 HANNOVER FAIR 2013

HANNOVER FAIR 2012 HANNOVER FAIR 2012

HANNOVER FAIR 2011 HANNOVER FAIR 2011

HANNOVER FAIR 2010 HANNOVER FAIR 2010

Arno's

Forum Interview 2010 Arno's

Forum Interview 2010

HANNOVER FAIR 2009 HANNOVER FAIR 2009

Arno's Video during HF 2009 Arno's Video during HF 2009

Arno's Forum Interview 2009 Arno's Forum Interview 2009

HANNOVER FAIR 2008 HANNOVER FAIR 2008

Arno's Forum Interview 2008 Arno's Forum Interview 2008

HANNOVER FAIR 2007 HANNOVER FAIR 2007

Arno's Forum Interview 2007 Arno's Forum Interview 2007

HANNOVER FAIR 2006 HANNOVER FAIR 2006

Daily Networking evenings Daily Networking evenings

HANNOVER FAIR 2005 HANNOVER FAIR 2005

Daily Networking evenings Daily Networking evenings

International

Commercial Visitors 2005 International

Commercial Visitors 2005

HANNOVER FAIR 2004 HANNOVER FAIR 2004

International

Commercial Visitors 2004 International

Commercial Visitors 2004

HANNOVER FAIR 2003 HANNOVER FAIR 2003

International

Commercial Visitors 2003 International

Commercial Visitors 2003

HANNOVER FAIR 2002 HANNOVER FAIR 2002

HANNOVER FAIR 2001 HANNOVER FAIR 2001

HANNOVER FAIR 2000 HANNOVER FAIR 2000

HANNOVER FAIR 1999 HANNOVER FAIR 1999

HANNOVER FAIR 1998 HANNOVER FAIR 1998

HANNOVER FAIR 1997 HANNOVER FAIR 1997

HANNOVER FAIR 1996 HANNOVER FAIR 1996

HANNOVER FAIR 1995 HANNOVER FAIR 1995

|

| |

| Visits and Workshops |

|

Hans-Olof Nilsson's Off-The-Grid Hydrogen House near Goteborg, Sweden Hans-Olof Nilsson's Off-The-Grid Hydrogen House near Goteborg, Sweden |

|

Visit at the Italian demonstration plant of MagneGas⢠on February 7th and 8th, 2011 Visit at the Italian demonstration plant of MagneGas⢠on February 7th and 8th, 2011 |

|

Hydrogen Plant of Emirates Industrial Gases Co. Ltd ( EIGC) at Dubai, UAE Hydrogen Plant of Emirates Industrial Gases Co. Ltd ( EIGC) at Dubai, UAE |

|

Huerta Solar en Tabernas, Spain, October 2009 Huerta Solar en Tabernas, Spain, October 2009 |

|

Andasol, Spain, October 2009 Andasol, Spain, October 2009 |

|

Antares DLR H2, Stuttgart, Germany,

September 2009 Antares DLR H2, Stuttgart, Germany,

September 2009 |

|

German Aerospace Center (DLR) Deutsches Zentrum für Luft-und Raumfahrt eV, Stuttgart, Germany, Institute of Technical Thermodynamics (ITT) Institute of Vehicle Concepts Stuttgart, Germany, June 2009 German Aerospace Center (DLR) Deutsches Zentrum für Luft-und Raumfahrt eV, Stuttgart, Germany, Institute of Technical Thermodynamics (ITT) Institute of Vehicle Concepts Stuttgart, Germany, June 2009 |

|

Brennstoffzellen-Boote für den Freizeitbereich, Hochschule Konstanz, Konstanz, Germany June 2009 Brennstoffzellen-Boote für den Freizeitbereich, Hochschule Konstanz, Konstanz, Germany June 2009 |

|

AFCC Automotive Fuel Cell Cooperation, Burnaby, BC, Canada June 2009 AFCC Automotive Fuel Cell Cooperation, Burnaby, BC, Canada June 2009 |

|

Powertech Labs Inc., a: "... wholly owned subsidiary of BC Hydro (a Crown corporation of the Government of British Columbia), Surrey, BC, Canada June 2009 Powertech Labs Inc., a: "... wholly owned subsidiary of BC Hydro (a Crown corporation of the Government of British Columbia), Surrey, BC, Canada June 2009 |

|

Plataforma Solar de Almería, Spain Plataforma Solar de Almería, Spain |

|

| Observations |

|

How Airbus conquered the How Airbus conquered the

US market in the 70s |

|

The Arecibo Observatory The Arecibo Observatory

Arecibo, Puerto Rico |

|

Hat Creek Radio Observatory, Hat Creek Radio Observatory,

Hat Creek, CA, USA |

|

National Radio Astronomy Observatory, Green Bank, WV, USA National Radio Astronomy Observatory, Green Bank, WV, USA |

|

Wright Brothers National Memorial, Kitty Hawk, NC, USA Wright Brothers National Memorial, Kitty Hawk, NC, USA |

|

Fuel Cell Bus Trial, Perth, Australia Fuel Cell Bus Trial, Perth, Australia |

|

California Hydrogen Highway, USA California Hydrogen Highway, USA |

|

SPACEFEST 2009, San Diego, USA SPACEFEST 2009, San Diego, USA |

|

| Impressions from worldwide Conferences, which

we attended to promote the commercialisation of Hydrogen and Fuel

Cells: |

| 2022 |

| #117 |

2nd Edition of International

Conference on

Green Chemistry and Renewable Energy |

| 2020 |

| #116 |

2020 6th International

Conference on Environment and Renewable Energy (ICERE 2020), 24-26 February 2020, Hanoi, Vietnam |

| 2019 |

| #115 |

4th Annual ASEAN Solar +

Energy Storage Congress & Expo 2019 14- 15 Nov, 2019 The Bellevue Manila, Philippines |

| #114 |

SFERA-III 1st Summer School &

Doctoral Colloquium at CNRS-PROMES in Odeillo, France

September 9th-13th, 2019 |

| #113 |

Starmus V, June 24 â 29, 2019

Zurich, Switzerland a global festival of science communication and art |

| 2018 |

| #112 |

Visit to NOORo I to III in

Ouarzazate, Morocco as part of the SolarPACES 2018 conference, October 6, 2018 |

| #111 |

The Hydrogen Energy Summit

2018 Chiang Mai, Northern Thailand Arno's presentation: Off the Grid â Unveiling new ways for our Energy supply January 26, 2018 |

| 2015 |

| #110 |

1. Klimaschutzkongress auf der

Insel Sylt

25. September 2015

Vortrag von Arno A. Evers:

Eine âInsel- Lösungâ für Sylt?

Neue Wege zur Energieversorgung der Insel Sylt |

| 2014 |

| #109 |

6. Hamburger Klimawoche

29. August 2014

Vortrag von Arno A. Evers:

Physikalische und Gesellschaftliche Rahmenbedingungen der Energiewende010 |

| 2012 |

| #108 |

MesseKongress RegioEnergie+++  Dreieich 2012 Dreieich 2012

9. September 2012

Vortrag von Arno A. Evers: Sind wir noch zu retten? |

| 2010 |

| #107 |

WREC World Renewable Energy Congress XI

September 25-30, 2010

Abu Dhabi, United Arab Emirates

Oct 2010 |

| #106 |

18th World Hydrogen Energy Conference WHEC 2010,

May 16 - 21

Essen, Germany

Jun 2010 |

| 2009 |

| #105 |

"Bright

Horizons 6" -

A Journey

to the Edge of the Cosmos

Eastern Caribbean

Dec 2009 |

| #104 |

2009 Fuel Cell Seminar & Exposition

Palm Springs, CA, USA

Nov 2009 |

| #103 |

Fuel Cell Technologies:

FUCETECH 2009

Mumbai (Bombay), India

Nov 2009 |

| #102 |

f-cell

Stuttgart, Germany

Sep 2009 |

| #101 |

SolarPACES 2009

Berlin, Germany

Sep 2009 |

| #100 |

5th Annual Hydrogen Implementation Conference

Charleston, WV, USA

Aug 2009 |

| #99 |

Intersolar North America

San Francisco, CA, USA

Jul 2009 |

| #98 |

European FUEL CELL FORUM 2009

Lucerne, Switzerland

Jun 2009 |

| #97 |

HFC2009

Vancouver, Canada

Jun 2009 |

| #96 |

telescon 2009

Vienna, Austria

May 2009 |

| #95 |

Hydrogen Works

San Diego, CA, USA

Feb 2009 |

| #94 |

ICEPAG 2009

Newport Beach, CA, USA

Feb 2009 |

| 2008 |

| #93 |

HTE-HI.TECH.EXPO 2008

Milan, Italy

Nov 2008 |

| #92 |

Fuel Cell Seminar & Exposition

Phoenix, AZ, USA

Oct 2008 |

| #91 |

H2Expo

Hamburg, Germany

Oct 2008 |

| #90 |

f-cell

Stuttgart, Germany

Sep 2008 |

| #89 |

INTELEC 2008

San Diego, CA, USA

Sep 2008 |

| #88 |

2008 Formula Zero Championship

Rotterdam, The Netherlands

Aug 2008 |

| #87 |

HyForum 2008

Changsha, P.R. China

Aug 2008 |

| #86 |

WREC X 2008

Glasgow, Scotland, UK

Jul 2008 |

| #85 |

KMCM 2008

Vancouver, BC, Canada

Jul 2008 |

| #84 |

Lucerne FUEL CELL FORUM 2008

Lucerne, Switzerland

Jun 2008 |

| #83 |

17th World Hydrogen

Energy Conference (WHEC)

Brisbane, Australia

Jun 2008

The role of the young generation ... The role of the young generation ... |

| #82 |

Renewable Energy Asia

Bangkok, Thailand

Jun 2008 |

| #81 |

Selected Hydrogen Fueling Stations in California, USA

Apr 2008 |

| #80 |

NHA Annual Hydrogen Conference 2008

Sacramento, CA, USA

Mar / Apr 2008 |

| #79 |

FC EXPO 2008

Tokyo, Japan

Feb 2008 |

| #78 |

Der 4. Deutsche Wasserstoff

Congress 2008

Essen, Germany

Feb 2008 |

| #77 |

ISEPD 2008

Changwon, Korea

Jan 2008 |

| 2007 |

| #76 |

20TH World Energy Congress & Exhibition

Rome, Italy

Nov 2007 |

| #75 |

World Hydrogen Technologies Convention (WHTC)

Montecatini Terme, Italy

Nov 2007 |

| #74 |

2007 Fuel Cell Seminar & Exposition

San Antonio, Texas, USA

Oct 2007 |

| #73 |

KOREA ENERGY SHOW 2007

Seoul, Republic of Korea

Oct 2007 |

| #72 |

Tenth Grove Fuel Cell Symposium

London, UK

Sep 2007 |

| #71 |

Solar Tech India 2007

New Delhi, India

Sep 2007 |

| #70 |

SES-Fachtagung

MYTHOS STROMLÜCKE

Zurich, Switzerland

Aug 2007 |

| #69 |

HFCE 2007

Shanghai, P.R. China

Jul 2007 |

| #68 |

IHEC 2007

Istanbul, Turkey

Jul 2007 |

| #67 |

KMCM 2007

Düsseldorf, Germany

Jul 2007 |

| #66 |

Kick Off Meeting zur Leitinnovation Mikrobrennstoffzelle

Munich, Germany

Jun 2007 |

| #65 |

Hydrogen and Fuel Cells 2007: International Conference &

Trade Show

Vancouver, BC, Canada

April / May 2007 |

| #64 |

GENERA - Energy and Environment International Fair

Madrid, Spain

Feb / Mar 2007 |

| #63 |

World Renewable Energy Congress [WREN]

Fremantle, Australia

Feb 2007 |

| #62 |

Environment 2007

Exhibition & Conference

Abu Dhabi, UAE

Jan 2007 |

| 2006 |

| #61 |

2nd Annual Fuel Cells Durability & Performance 2006

Miami Beach, FL USA

Dec 2006 |

| #60 |

EDTA Conference & Exposition

Washington, DC, USA

Nov 2006 |

| #59 |

The Fuel Cell Seminar

Honolulu, Hawaii, USA

Nov 2006 |

| #58 |

Fraunhofer Symposium

Mikroenergietechnik

POWER TO GO

Berlin, Germany

Oct 2006 |

| #57 |

Renewables to Hydrogen Forum

Albuquerque, NM, USA

Oct 2006 |

| #56 |

Alternative Transport Energies Conference

Perth, Western Australia

Sep 2006 |

| #55 |

Power-Gen Asia

Hong Kong, Hong Kong

Sep 2006 |

| #54 |

World Renewable Energy

Congress IX and Exhibition

Florence, Italy

Aug 2006 |

| #53 |

R&D in the field of Hydrogen and Fuel Cell in Germany and Europe

Clausthal, Germany

Jul 2006 |

| #52 |

Lucerne Fuel Cell Forum 2006

Lucerne, Switzerland

Jul 2006 |

| #51 |

16th World Hydrogen Energy Conference (WHEC)

Lyon, France

Jun 2006 |

| #50 |

NHA Annual Hydrogen Conference

Long Beach, CA, USA

Mar

2006 |

| #49 |

FC

EXPO 2006

Tokyo, Japan

Jan 2006 |

| #48 |

Wasserstoff und Brennstoffzellen im Automobil

Essen, Germany

Apr 2006 |

| 2005 |

| #47 |

Fuel

Cell Seminar

Palm Springs, USA

Nov 2005 |

| #46 |

Internationale

ASUE-Fachtagung

Essen, Germany

Nov 2005 |

| #45 |

EHEC

2005

Zaragoza, Spain

Nov 2005 |

| #44 |

Fuel

Cell Summit:

A Road Map to Commercialization

Uncasville, CT, USA

Oct 2005 |

| #43 |

2005

Grove Fuel Cell Symposium

London, UK

Oct. 2005 |

| #42 |

WHTC

2005 World Hydrogen Technologies Convention (WHTC) Singapore, Singapore

Oct. 2005 |

| #41 |

f-cell

2005, Stuttgart, Germany

Sep. 2005 |

| #40 |

The

27th International Telecommunications Energy Conference - intelec

'05

Berlin, Germany

Sep. 2005 |

| #39 |

IHK

Nord Wasserstoff – Tagung

Lübeck, Germany

Sep. 2005 |

| #38 |

ICHS

- International Conference on Hydrogen Safety , Pisa, Italy

Sep. 2005 |

| #37 |

IHEC-2005

International Hydrogen

Energy Congress & Exhibition

Jul. 2005 |

| #36 |

93.

Bunsen Kolloquium

Jun. 2005 |

| #35 |

European

Hydrogen and Fuel Cell Technology Platform (HFP)

Brussels, Belgium

Mar. 2005 |

| #34 |

Cairo

9th International Conference on Energy & Environment

Sharm El-Sheikh, Egypt

Mar. 2005 |

| #33 |

1st

International Fuel Cell Expo

Tokyo, Japan

Jan. 2005 |

| 2004 |

| #32 |

H2PS:

The 2004 Hydrogen Production and Storage Forum,

Washington, DC, USA

Dec. 2004 |

| #31 |

Impressions

from Shanghai

Nov. 2004 |

| #30 |

Renewable Energies China incl. Hydrogen + Fuel Cells

Shanghai, PR China

Nov. 2004 |

| #29 |

Michelin

Challenge Bibendum 2004

Oct. 2004 |

| #28 |

Energy

Asia 2004

Oct. 2004 |

| #27 |

Hydrogen

and Fuel Cells 2004

Conference and Trade Show

Toronto, ON, Canada

Sep. 2004 |

| #26 |

Meetings

in Singapore,

Sep. 2004 |

| #25 |

Hydrogen

and Fuel Cell Futures Conference, Perth, Australia

Sep. 2004 |

| #24 |

Exhibiting

at World Renewable Energy Congress VIII

Denver, CO, USA

Sep. 2004 |

| #23 |

Arno

presenting at ACS National Meeting Philadelphia, PA, USA

Aug. 2004 |

| #22 |

Promotion

of FP6, for European Union, Delegation of the European Commission,

Shanghai

Jul. 2004 |

| #21 |

IHK

Energy-Podium 2004

Jul. 2004 |

| #20 |

15th

World Hydrogen Energy Conference (WHEC15)

Yokohama, Japan

Jun. 2004 |

| #19 |

Impressions

from the

Energy Forum 2004

Varna, Bulgaria

Jun. 2004 |

| #18 |

Impressions

from HYFORUM

May 2004 |

| #17 |

Impressions

from Dubai

United Arab Emirates

May 2004 |

| #16 |

Impressions

from Argentina

May 2004 |

| #15 |

Promoting

Hydrogen Production from Patagonia, Argentina

May 2004 |

| #14 |

Impressions

Zhuozheng Garden

in Su Zhou

Mar. 2004 |

| 2003 |

| #13 |

H2PS:

The 2003 Hydrogen Production and Storage Forum

Washington, D.C., USA

Dec. 2003 |

| #12 |

Impressions

from

Washington, D.C., USA

Dec. 2003 |

| #11 |

Shanghai

International Industry Fair (SIF), Shanghai, P.R. China

Nov. 2003 |

| #10 |

Energy

Asia 2003

PTC Asia 2003

CeMAT Asia 2003

Factory Automation Asia 2003

Shanghai, P.R. China

Nov. 2003 |

| #9 |

2003

WATER KOREA

Nov. 2003 |

| #8 |

NESC

2003 - 6th Int'l Conference on New Energy Systems & Conversions

Nov. 2003 |

| #7 |

Impressions

from Busan

South-Korea

Nov. 2003 |

| #6 |

2003

Fuel Cell Seminar

Miami Beach, Florida, USA

Nov. 2003 |

| #5 |

Impressions

from Shanghai, Beijing, P.R. China

Nov 2003 - Jul. 2004 |

| #4 |

f-cell

forum, Stuttgart, Germany

Sep. 2003 |

| #3 |

Hypothesis

V, Porto Conte, Italy

Sep. 2003 |

| #2 |

1st

European Hydrogen Energy Conference, Grenoble, France

Sep. 2003 |

| #1 |

Cooperation

for Energy Independence of Democracies in the 21st Century

Jerusalem, Israel

Aug. 2003 |

|

|

|

|

|

Shanghai International

Industry Fair (SIF) 2004

|

|

|

|

| Corporate

Information |

| home |

|

|

|

|

|

|

Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR)

Institut für Technische Thermodynamik

Stuttgart,

Germany |

|

Booth Number:

F84/1 |

| |

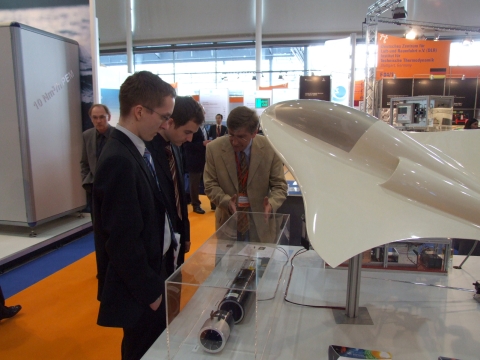

Representative of the German Aerospace Center, Werner Hoyer, explains the advantages of an oxygen operated system that Deutsches Zentrum fur Luft- und Raumfahrt applies within one of the world's first fuel cell propelled aircraft demonstrator models. The model measures 130cm by 100cm.

|

Engineers Christian Friedrich and Michael Kruger of DLR's German Aerospace Center explains the benefits of compact heat exchangers for mobile air-conditioning applications to a trade show participant.

VIP Visits:

|

Company Information

| Company Association

Name |

Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR)

Institut für Technische Thermodynamik |

| Website Address |

http://www.dlr.de/tt |

| Company Email |

itt@dlr.de |

| Number of employees |

145 |

| President CEO |

Prof. Dr. Dr. - Ing. Hans M\374ller Steinhagen |

| Name Media Contact |

Werner Hoyer |

| Name Human Resources |

Prof. Dr. rer.nat. Andreas Friedrich and

Dr. rer.nat. Rainer Tamme |

Company's Interests:

DLR is Germany's national research center for aeronautics and space. Its extensive research and development work is integrated into national and international cooperative ventures.

Approximately 5.100 people are employed in DLR's 27 institutes and facilities at eight locations in Germany.

The Institute of Technical Thermodynamics in Stuttgart (with additional sites in Cologne-Porz and Almeria, Spain) focuses its efforts on the realisation of high-efficiency energy conversion technologies useable and promoting the introduction of renewable energy sources. A total of 145 staff is dedicated to this task, whether through studies, fundamental laboratory research or the development of pilot facilities.

Its topics are: |

- Solar research

- Systems analysis and technology assessment

- In electrochemical energy conversion the main fields of investigation are fuel cell technologies for low and high temperatures, regenerative fuel supply and the market introduction of complete fuel cell systems. Starting from fundamental electrochemical research, the institute develops innovative manufacturing processes, diagnostics and system concepts for stationary, mobile and portable applications.

- Activities of the division "Thermal Process Technology” are directed to system and component technology in the research area thermal engineering and fuel processing. It covers highly efficient regenerative and recuperative heat exchanger and thermal energy storage systems as well as fuel processing and fuel conversion of hydrogen rich fuels to be applied for various fuel cell and gas turbine applications.

|

| |

Achievements in 2005:

The activities in the field of fuel cells are mainly devoted to improving power density, increasing life-time and reducing cost of fuel cells and stacks. DLR is mainly active in research and development of fuel cells for aircraft applications, auxiliary power units (APUs) as well as stationary energy supply. Diagnostic methods - like innovative approaches to measure the local current density and temperature with high resolution - have been developed at the Institute. Controls of cell and stacks based on the detailed information obtained from these measurements are under development enabling self-regulating of cells and stacks. DLR has developed proprietary manufacturing methods for low and high temperature fuel cells. For polymer electrolyte fuel cells a low cost, dry rolling technique for membrane-electrode production is used which has shown superior performance especially for direct methanol fuel cells. But also for hydrogen polymer electrolyte fuel cells this manufacturing method stands out regarding its cost-effectiveness and flexibility. Thin layer solid oxide fuel cells (SOFC) manufactured by plasma spraying in planar design for temperatures around and below 800 °C have been developed. The metal-supported cells of DLR are especially suited for dynamic operation and are stable against fast temperature changes and redox cycles. Therefore, they are designed to be used as engine independent electrical power sources (Auxiliary Power Units (APU)). |

| |

News at HANNOVER FAIR 2006:

The displayed exhibit shows the operation of a fuel cell with special bipolar plates based on printed circuit board technology enabling the measurement of current distributions. An PEFC-system with a power output of 360 W which operates an impeller of an unmanned aircraft “HyFish”. This aircraft is suited to demonstrate the performance of a fuel cell system in a challenging environment and to demonstrate an efficient air-independent fuel cell system for various applications. |

| |

| |

|

|

| Click

here for our exhibitor's online documentation - HANNOVER FAIR

'05 |

| http://www.dlr.de/tt

|

|

Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR) - Institut für Technische Thermodynamik is participating in the Forum. Click here to find details. |

|

|

|