|

|

Visit at the Italian demonstration plant of MagneGas™ on February 7th and 8th, 2011

Here I had the opportunity, to see their Plasma Arc Through™ Refinery System at work. I was most impressed with what I saw. They are converting liquid biomass of all kinds, like sewage overflow or sludge into a gas, called MagneGas™. At this time, the MagneGas™ is mainly used as a technical gas for welding and other purposes. However, the technology is highly potential also for additional important usages in our energy infrastructure.

If the electricity used in this process is coming from Renewable Energies, which is possible, this can be called a renewable waste--to-energy process. I was most impressed.

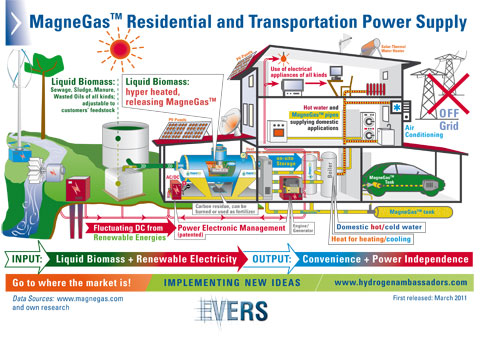

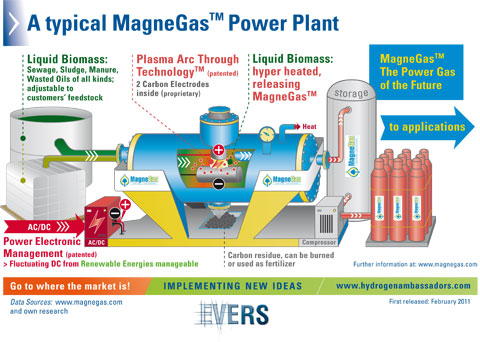

A typical MagneGas™ Power Plant

Print version (pdf)

This is a mobile installation; liquid biomass like Sewage, Sludge, Manure, Wasted Oils of all kinds; can be fed in

The MagneGas ™ process can be adjusted to the liquid biomass feedstock, which is available at customer`s site…

The test and demonstration installation in Italy is raising interest by European visitor groups from Industry, Politics and Science…

This is the heart of the unit: Here the patented Plasma Arc Flow™ Technology takes place, at two Electrodes inside the blue tubes with yellow fittings.

The equipment is easy to operate and to maintain, Alessandro Ciotta at work...

The start up time is rather short, after 15 minutes everything is running smoothly...

Patented Power Electronic Management to ensure optimum Arc operation at 10.000 °F (5.500° Celsius)…

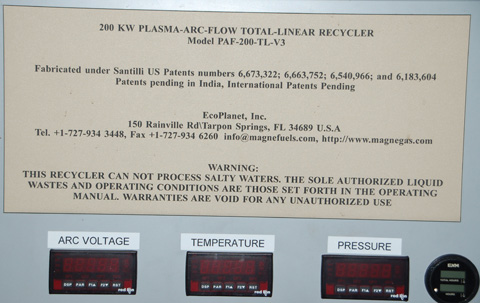

The company MagneGas has it`s headquarter in Tarpon Springs, Florida, USA...

The electricity can be variable, also generated from Renewable Energies; fluctuations do not interrupt the process...

The equipment stays cool and can be touched at any time...

These are the original electrodes before they are used in the process...

The MagneGas™ is compressed and filled into bottles. The filing process is easily handled, as seen here

The result of the gasification is carefully monitored...

The MagneGas™, which is created and used here, reaches repeatable far better combustion greenhouse gases values than petrol and natural gas...

| Methane | Natural gas | MagneGas™ Sample I | MagneGas™ Sample II | |

| Test date | 12/09/2010 | 12/09/2010 | 12/09/2010 | 02/8/2011 |

| CO %vol | 2.537 | 2.134 | 0.359 | 0.022 |

| CO2%vol | 10.050 | 12.350 | 6.880 | 6.700 |

| HC ppm vol | 169 | 300 | 1 | 0 |

| 02 % vol | 0.570 | 1.160 | 13.330 | 11.85 |

| NO | 44 | 273 | 1 | 0 |

| CO cor | 2.537 | 2.210 | 0.595 | 0.039 |

| Λ | 0.9290 | 0.9760 | 1.9040 | 1.8830 |

| Temp 0C | 93 | 99 | 52 | 45 |

| Amb. Temp 0C | 18 | 18 | 17 | 12 |

| Pressure hPa | 995 | 994 | 996 | 1008 |

This is the main application at this time: MagneGas™ used for welding...

This early prototype shows the development in the MagneGas™ technology...

Thumbs up for the progress of the MagneGas™ test and demo equipment for New Power Plants...

Your contact in Europe:

Ermanno Santilli

Magnegas Arc Applied Solutions Europe (MAASE)

ermanno_santilli@me.com

Skype:

ermomony

Facebook: MagneGas

LinkedIn: MagneGas

+32 4 7417 3537

Your contact in the USA:

Corporate Address

MagneGas Corporation

150 Rainville Rd

Tarpon Springs, FL 34689

Phone 727-934-3448

Fax 727-934-6260

www.magnegas.com

http://ir.stockpr.com/magnegas/media-center/view/183/corporate-video