|

|

Visit at the U.S. headquarter of MagneGas™ in

Tarpon Springs, Florida, March 14-15, 2011

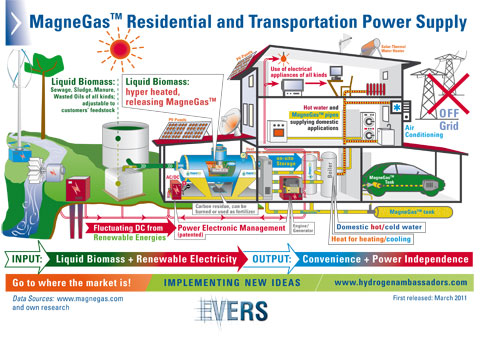

I visted MagneGas™ Corporation headquarter at Tarpon Springs, FL, USA, in March 2011 and was most impressed and also motivated, with what I saw there. The question, how to achieve a Hydrogen Society, has not been solved today. The production of hydrogen as an energy carrier was and is tackled by many since years, but only a few have come to commercial viable solutions. MagneGas™ is a patented technology which produces a gas called MagneGas from renewable bio-liquid waste streams. When implementing this unique waste-to-energy power generation into a decentralized, new energy infrastructure, much can be gained: We will save natural resources and create a cleaner environment at the same time.

Dr. Ruggero Maria Santilli (right), Chairman of the Board, Chief Executive Officer, MagneGas™ Corporation, together with Frank B. Choi, Chairman of BBN PARTNERS, Rewable Waste & Energy, Kowloon, Hong Kong and also Chief of Operations (COO) of KD POWER Co., Ltd., Seoul, Korea...

Scott Wainwright, President, MagneGas™ Corporation, at a welding demonstration using MagneGas™. The gas is environmental friendly, burning with a clear flame of high temperatures...

MagneGas™ can be used for clear cutting of metals, as this example demontrates...

MagneGas™ can be used for clear cutting of metals, as this example demontrates...

Scott Wainwright, President, MagneGas™ Corporation, explaining the advantages of the Magnegas welding to Frank B. Choi (right), Chairman of BBN PARTNERS, Rewable Waste & Energy, Kowloon, Hong Kong and also Chief of Operations (COO) of KD POWER Co., Ltd., Seoul, Korea (see below)...

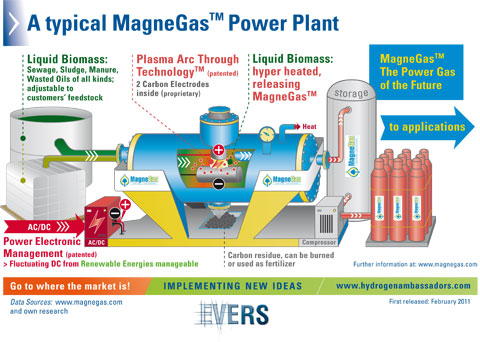

The Power Electronic Management of the MagneGas™ ower Plants is patented by MagneGas™ Corporation

The actual refineries are running quietly and emit no odor or noise pollution...

This MagneGas™ Demonstration Plant is used for cleaning sewage water, it is mounted on a trailer for mobile applications of all kinds...

Before and after the treatment with the Plasma Arc Flow™ of sludge or overflow, with the potential to produce water for irragation...

#

#

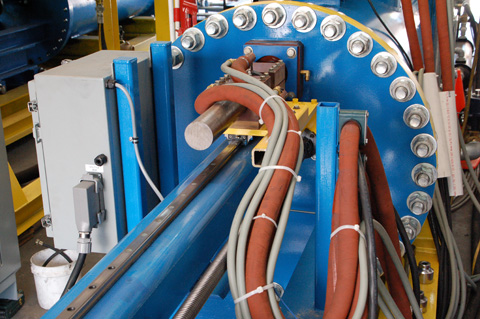

The electrodes are an important feature of the MagneGas™ process. Between them, the patented Plasma Arc Flow™ Refinering Systems is created, which is superheating the liquid waste to make the MagneGas™...

The electrodes are tailor made according to the feedstock used in the MagneGas™ process, to convert liquid waste (i.e. sewage, sludge, animal manure, glycerin, used antifreeze, oil-based liquids and waste water into MagneGas™ ...

MagneGas™ is at this time mostly used as a welding and cutting gas for the Metal-Working-Market, where excisting fuels emit highly toxic emissions; MagneGas™ is still the only current *green* fuel alternative...

The filling of the MagneGas™ bottles is easy and done permanent onsite for various customers...

The actual refinery needs a small footprint only, mobility and ease of installation enables production of MagneGas™, wherever needed...

Gino M. Amato, Head of Procurement MagneGas™ Corporation...

Dr. Ruggero Maria Santilli pointing at the gas-inlet at a car, which already attended at a racing at the Italian Monza Formular 1 Racetrack... http://www.monzanet.it/en

Vehicles of all kinds can easily run on MagneGas™. They *only* need to have a combustion engine (ICE), which has to be modified for operating on the special gas. Even a bi-fuel-operation with either petrol or MagneGas™ is possible and no problem at all...

Dr. Ruggero Maria Santilli (left), Chairman of the Board, Chief Executive Officer, MagneGas™ Corporation, together wit Arno A. Evers, FAIR-PR, Starnberg, Germany. Photo thanks to: Frank B. Choi (right), Chairman of BBN PARTNERS, Rewable Waste & Energy, Kowloon, Hong Kong and also Chief of Operations (COO) of KD POWER Co., Ltd., Seoul, Korea...

A typical MagneGas™ Power Plant

Print version (pdf)

Your contact in Europe:

Ermanno Santilli

Magnegas Arc Applied Solutions Europe (MAASE)

ermanno_santilli@me.com

Skype:

ermomony

Facebook: MagneGas

LinkedIn: MagneGas

+32 4 7417 3537

Your contact in the USA:

Corporate Address

MagneGas Corporation

150 Rainville Rd

Tarpon Springs, FL 34689

Phone 727-934-3448

Fax 727-934-6260

www.magnegas.com

http://ir.stockpr.com/magnegas/media-center/view/183/corporate-video